SKF Flowline 1000

Oil circulation systems are commonly found in areas where bearings are subjected to extreme conditions such as high speeds or high operating temperatures. Bearings can be crippled by excessive heat and unfortunately grease does nothing to lower the local temperature of the bearing. Oil on the other hand is very effective at transferring heat and serves a dual function of providing a lubrication barrier between the bearing and it's contact surfaces.

Traditional oil circulation systems consist of a settling tank, typically outfitted with a baffle to provide turbulence, motors, filters, gauges etc. These systems were originally designed around a specific holding time which would allow for any trapped water or air to separate from the oil before recirculating to the bearing.

These original circulation systems were created long before computers existed. Trying to predict the path of fluid particles through a system by hand is an incredible challenge. As computers have grown more powerful over the years, it has become possible to better predict the behavior of fluids in a system. This area of simulating flows, tracking fluid velocities, pressures etc. is known as computational fluid dynamics or CFD for short.

A skilled engineer can use CFD software, such as fluent, along with hand calculations to paint a much clearer picture of what is going on inside of a traditional settling tank.

What SKF has discovered is that rather than settling, the return oil forms a slip stream, or short circuit, between the return and the supply lines. This phenomena negates any chance for the oil/air/water solution to separate before returning to the bearing. While this might not sound like a serious issue, the overall life of a bearing is heavily dependent on the oil being clean, dry, and air free.

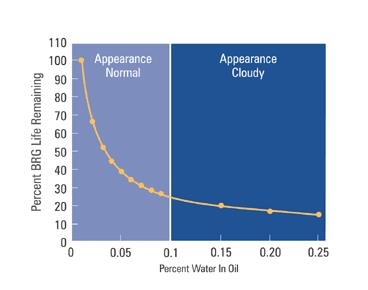

How dry does the oil need to be to avoid compromising the life of a bearing?

A bearing can lose as much as 75% of its usable life before the oil even becomes cloudy, that is, before the water saturation reaches 100 ppm or .1%. In case you missed that... we are talking about one ten thousandth of a part of water to one part oil (.001 : 1). All it takes is little more than a cup of water in a hundred gallon tank of oil to strip away fifteen years of life off of every bearing in the system.

Water contamination is a silent killer for bearings and without routine testing an organization would be none the wiser of the catastrophic effect water saturated oil has on their equipment.

Realizing that traditional bowser style circulation systems are far from perfect, SKF set out to create a new design for an oil circulation system that outpaces any competitor's ability to condition and circulate lubricant for bearings operating under extreme conditions.

Whats so different about SKF's Flowline Circulation System?

When it comes to removing water and air from oil there isn't any black magic involved. The separation occurs naturally given enough time. Water is heavier than oil and tends to sink until separation. Air does the opposite rising until separation.

The key to the Flowline's efficiency centers around maximizing the amount of oil in circulation and minimizing the distance the water and air needs to travel to escape the oil.

Smaller traditional system's have settling tanks that are approx. 3 feet tall. In order for water and air to separate from the oil it needs to travel a foot and a half on either side before it can escape.

The characteristic shape of SKF's plate separator technology reduces the travel distance needed for a water particle to escape from 18" to just 3". This reduction in travel distance allows SKF's Flowline system to effectively remove more than 90% of trapped water from the circulating oil -- 2x-3x more efficient than traditional counterparts. The geometry of the tank also prevents any still oil from collecting in the reservoir which is common to many traditional systems. This ensures that a majority of oil in circulation is able to be conditioned and cleaned before returning to service bearings.

In conclusion, SKF Flowline Oil Circulation Systems are truly the next evolutionary step in the lubrication world. Bearings that see a constant barrage of extreme speeds/temperature, increased contamination of solid particles, and or excessive water ingress will stand to benefit greatly from a new Flowline system. If you employ expensive bearings on your manufacturing line, or if a bearing failure leads to costly lost production it would worth a short discussion to learn more about the expected return on investment by upgrading an existing oil circulation system. Click Here for more information about SKF's Flowline Circulation Oil System.

If you would to learn more about the SKF's Flowline Technology or perhaps set up a meeting to discuss your particular application with Foursquare as well as one of SKF's lubrication specialist please feel free to contact Cleve Hudspeth, 804-748-5523, cleve.hudspeth@foursquareindustrial.com and he will gladly assist you in whichever capacity your organization deems necessary.