What is an Automated Lubrication System?

Unexpected shutdowns are expensive, frustrating, and seemingly unpredictable. Couple that fact with the stress of international manufacturers competing for American business and its clear that efficiency and reliability have become more important now than they ever have been in the history of industry.

These two pillars of production have been at the forefront of every revolution in today's modern industrial practice. With each step, we find ourselves striving to out produce our competition while at the same time fighting to reduce overall operational cost of our machinery. With the demand for increased production capacity on the rise, many companies choose to track performance metrics to help quantify their plants viability. However, Many of the most common metrics place an emphasis machine up time which happens to be heavily dependent on plant maintenance.

This struggle reveals the ongoing tug of war between reliability and production departments across the country. Sadly, production and reliability share the same goal: keep the machine Running. However, maintenance is to often viewed as an inconvenience to be pushed aside until the next down day.

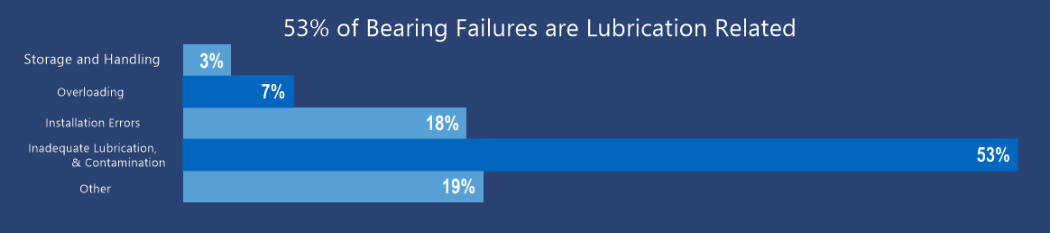

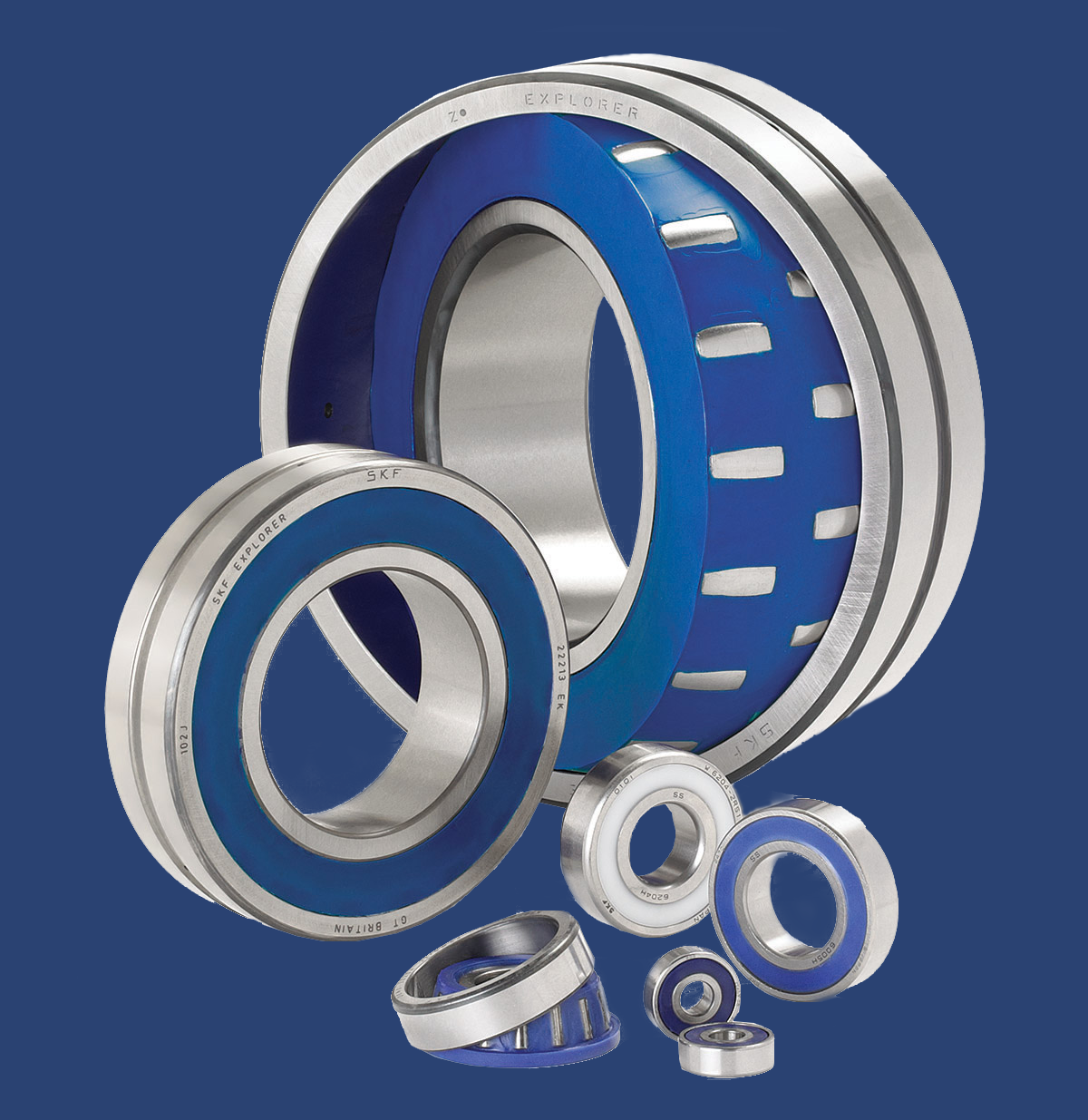

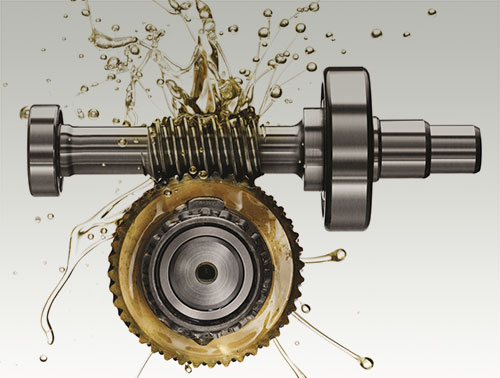

As maintenance is restricted so to is lubrication and lubrication requirements exist independently of a company's production schedule. Bearing life and performance are foundational to any plant's efficacy. Bearings large and small perform much better when they are frequently supplied with a thin film of lubricant -- multiple times throughout the day. However, for a company stuck in the manual mindset it will never be practical from an operational standpoint to achieve these standards.

The solution for many is to pack bearings with plenty of grease, cross their fingers, and wait until the next scheduled outage. This places the bearing in non-ideal situation. Bearings become subjected to a constant cycle of over and under lubrication and at the same time face exposure to contamination and excessive heat. These extreme conditions take years off of a bearing and often lead to lost production and increased maintenance spending.

Cue Your New Lubrication System...

While most manual lubrication programs are scheduled around planned machine downtime, a centralized lubrication system bypasses the human element and ensures that the perfect amount of lubricant is being delivered to the machine’s bearings at the most critical time -- while the machine is still running. A well designed automated system removes the need for skilled maintenance personnel to babysit hundreds of bearings. This not only reduces frustration but also labor and material costs.

Extended bearing life is the most noticeable consequence of a new lubrication system however the new system brings along with it a ripple effect of additional benefits. Right away, your maintenance team will be able to reallocate their focus to more critical areas of the plant which serves to improve overall plant health. With increased bearing health companies will also begin to realize less downtime and lost production. This ultimately takes shape in increased plant performance and additional revenue for the organization.

Automated lubrication serve to benefit a wide range of applications including... Mobile Construction Equipment, Food and Beverage, Pulp and Paper, and More..

About Us…

Four Square Industrial Constructors has been partnered with SKF-Lincoln since Janauary 1st, 2018. FSIC, at our core, we are an industrial construction company with a long standing reputation for finishing jobs on time if not ahead of schedule. We employ skilled engineers and technicians to service your organization lubrication needs from an initial audit of your existing equipment all the way through design and installation. We are an Authorized Distribution and Service Center for SKF-Lincoln Lubrication Systems-- fully backed by SKF to perform all system installation and repair work in the state of Virginia.

There exists a broad range of system types each with their own defining characteristics. This wide variety of systems allows for solutions to be tailored around your lubrication needs and most importantly your price point. At any level of investment, the end user of an automated lubrication system can ensure extended bearing life, reduced lubricant consumption, increased production time -- most importantly is the increased peace of mind come standard with any new automated lubrication system.

If you are experiencing a similar pain as described above, please feel free to contact Cleve Hudspeth, 804-748-5523, cleve.hudspeth@foursquareindustrial.com, and he will gladly assist you with your specific application ...